Like most developed countries, UK households and businesses benefit from extensive water infrastructure that has been constructed and upgraded over many decades. People previously confident of a steady and reliable source of clean water and access to wastewater treatment systems are becoming increasingly aware of water shortages.

Unfortunately, in addition to ongoing concerns about the management of wastewater treatment in many areas of the country, wastewater treatment facilities can carry a hidden environmental cost. Even when a plant successfully avoids the discharge of untreated water into the environment, many legacy systems produce undesirable by-products with a high Global Warming Potential (GWP), in addition to being incredibly energy intensive.

While there has been a significant shift toward self-generated renewable sources of power, the UK water industry remains the country’s fourth most energy-intensive sector, consuming 3% of total electricity production while generating 1% of all carbon emissions[1]. Cutting power consumption will be a key part of any net zero strategy, in addition to the continued transition to self-sufficient green power sources.

However, unlike communities in some developing nations, UK water companies aren’t starting with a blank piece of paper and have existing functional infrastructure. Uprooting this existing infrastructure would cause widespread disruption, plus in many areas, land constraints mean it simply is not feasible to build a completely new system. Of course, this is also before we ask where the funding for this type of investment is going to come from!

Obviously, these hurdles mean that existing facilities are not going anywhere and will need to be part of any new more sustainable wastewater treatment solution. Water companies should therefore be prioritising investment in flexible technologies that can be used to upgrade their current infrastructure through process intensification, increasing its efficiency, and improving their overall environmental footprint quickly and easily.

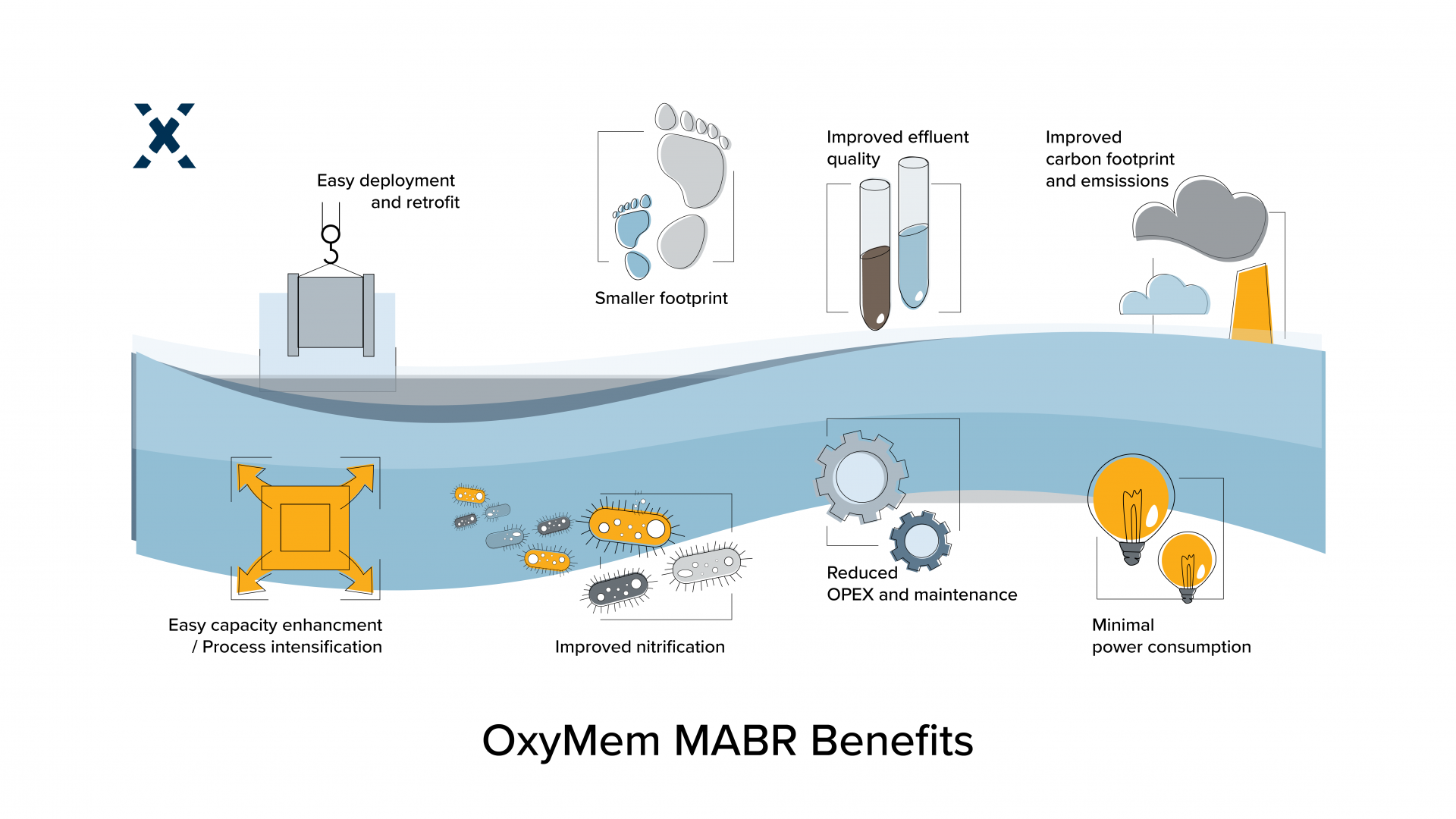

Membrane aerated biofilm reactors (MABR) are one of the solutions which could be a real difference maker as they can be deployed in activated sludge plants to increase treatment capacity or to replace legacy aeration systems in their entirety. This breakthrough technology offers exceptional energy efficiency and flexibility while reducing the volume of green-house gas produced during the biological treatment of wastewater.

In a conventional activated sludge plants, nutrients and pollutants are removed from wastewater in large aeration tanks using floating micro-organisms. These micro-organisms need to be fed with oxygen to ensure they continue to break down waste, and this is traditionally supplied by pumping air through diffusers to create bubbles. Unfortunately, this is incredibly energy-intensive, and the micro-organisms suspended in the tank often struggle to consume the oxygen contained within the fast-rising bubbles before they are released to the air and thus reducing the overall efficiency of the system.

An MABR module handles this process differently, containing membranes which carry a flow of oxygen at low pressure, creating optimal conditions for microbial growth and increasing the efficiency of the resultant micro-organisms. A robust biofilm rapidly forms on these membranes, providing a high rate of nutrient removal while reducing energy consumption by up to 75% when compared to the traditional aeration systems which have been used for over 100 years.

Consistent year-round performance is another advantage of MABR. Cold weather and changes in loading during winter months can cause issues with nitrification processes at conventional plants with suspended biomass, due to the slowed metabolism of micro-organisms and increased flow due to rain and snow. However, in an MABR, the nitrifiers are not at risk of being washed away by increased water flows as the biofilm is securely attached to the membranes, and the module is designed to provide resilience against seasonal changes by stabilizing the volume of COD in effluent.

In addition to consistently reducing energy consumption and any potential associated carbon emissions, including nitrous oxide which is created during the nitrification and denitrification phases.

Nitrous oxide is the world’s largest ozone-depleting substance emitted because of human activities, with a GWP approximately 300 times greater than carbon dioxide and potency comparable to chlorofluorocarbon CFC gases whose use was curtailed several decades ago due to their environmental impact. Recent studies suggest that nitrous oxide emissions from MABR system are significantly lower than nitrous oxide emission from activated sludge systems.

The UK water sector was the first in the world to reach an agreement on a plan to deliver net zero supplies to customers and it is already clear that MABR can play a big role in the realisation of that strategy.

OxyMem(TM) MABR technology has been selected for use in the transformative Triple Carbon Reduction project led by Anglian Water. This innovative project, to reduce water treatment greenhouse emissions and electricity use while providing a renewable source of green hydrogen, has received more than £3.5 million of funding from Ofwat.

However, it would be a mistake to dismiss MABR as something merely for the future. Last year, following a successful trial in their testing facility, Severn Trent decided to install 10 OxyMem(TM) MABR modules into a line at the Spernal Wastewater Treatment Plant. The new deployment was intended to enable consistent year-round processing of ammonia from imported sludge centrate as previously they had struggled during the winter months and been forced to pause imports.

Over just a couple of days, the modules were dropped into the live anoxic zone. A biofilm was subsequently established within two and half weeks, providing additional nitrification of approximately 13%. The plant is now benefitting from an expanded treatment capacity within the existing footprint with an average removal rate of 29 kgN/d, which is a nitrification rate of 2.0 gN/m2.d.

Ultimately, what sets MABR modules apart from alternatives is their ability to be ‘dropped in’ to existing systems without any interruption to existing operations. Whether they are intended to increase capacity or improve the effluent quality, installation can be completed over a couple of days without tank draining or pausing operation. Making use of existing aeration basins the modules don’t increase the footprint of operations or require additional infrastructure.

MABR is still a young technology, but these real-world results show that affordable and rapidly deployable upgrades to wastewater treatment facilities are now readily available. We don’t have to wait for some future innovation to play our part in the journey to net zero, the technology is already at our fingertips.