Every few decades, infrastructure needs to be upgraded. This is true in every industry, but for sectors with annual budgets, like the water industry, it can be hard to justify the long-term investment required to replace obsolete infrastructure that is no longer fit for purpose. Here, Matt Baldry, Director at I-Phyc, makes the case for investing in new P-removal infrastructure…

Chemical dosing is well and truly at the end of its tether for a vast number of reasons. Since the last AMP, the only way to get down to tolerant P levels is double dosing, and that’s already only doable at large plants that have a steady flow. There’s sludge removal to pay for, caustic dosing in soft water areas and, on top of all of that, the actual supply of ferric is deeply unstable.

In the very near future, the high levels of iron that wind up in the effluent after chemical dosing won’t be tolerated, and the P restrictions will of course get tighter. So, it simply cannot carry on, the technology is not soon-to-be obsolete, it’s already there.

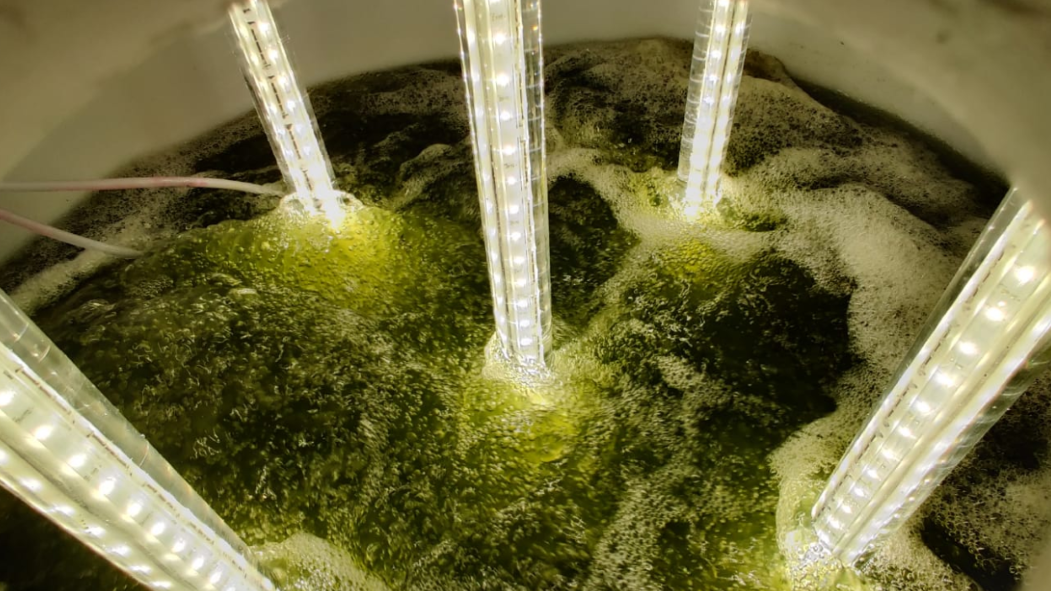

The good news is the successor technology, Bio-P removal, is ready to go and actually in situ at a few plants across the country already. The technology, which uses microalgae, has been shown to remove P to levels well below the limits of the current (and future) AMP(s). As well as phosphorus, it also removes ammonia, all in a single process without effecting each other’s performance. The technology is modular, has a small footprint and works with variable flows, so it’s appropriate for plants of varying sizes.

The only by-product is excess microalgae, which again is a resource and not a waste product. We can harvest biomass for use in agriculture or even sustainable printer ink, closing the loop of a truly circular economy.

The case for investing in infrastructure seems open and shut, in theory. But long-term investments and annual budgets aren’t ready bedfellows, so how can we justify the upgrade in terms of an annual budget?

One difficulty is that it’s just not straightforward to compare the two systems, because they are not like for like. The cost will always depend on the size of the treatment works that the system is working on. But what we can do is list the costs of each approach.

Ferric dosing has costs related to the chemicals themselves, the processing of the system which includes toxic sludge removal from the site and the disposal of it. The other side of ferric is the training of staff of how to use the chemicals safely, there’s the annual maintenance of the infrastructure, and there is also the cost of maintaining showers onsite in case of spillage. All of these things are a clear financial cost, but there’s also the environmental cost, a carbon cost, and the cost of risk keeping these chemicals near our water courses.

It’s a very different story with bio-P removal – the major upfront cost is the tank and flow system, and the cost in space the bioreactors take up, which is ultimately limited. They do need to be on hard, level ground, so you might face that cost if no such space exists at your plant.

In terms of ongoing costs, the microalgae itself is free and self-sustaining. There is a modest energy cost to power the LED lamps and air blowers which keep the microalgae healthy, and there is an energy cost to separate the algae from the clean water.

Offsetting all of this is the enormous environmental benefits of a chemical-free, sludge-free, carbon negative process that allows you to harvest the phosphorus and ammonia it removes and excess microalgae it produces as commodities with inherent monetary value. For example, I-Phyc’s Bio-P removal system can lock away 17 tonnes of CO2 per year at 1,000 population equivalent works. By 2030, this could equate to a modest, but not insignificant, £650 annual revenue.

The totex costs of installing an I-Phyc solution are competitive, it is more effective at removing P, and the system is environmentally friendly. In other words, it’s a win, win, win.