Pump Stators are vital for pump efficiency within Progressing Cavity Pumps, with a stator failure being potentially disastrous. Typically manufactured in a variety of rubbers or plastic, their shape forms that of a pump rotor, which work together to ensure fluid motion is always forward, with the parts acting as internal valves within the pump, preventing fluid from flowing back towards the inlet (positive displacement). Progressing Cavity Stators can often last years, however from experience they can also fail much sooner for a combination of reasons.

1. Fluid Temperature

The tolerances between a pump rotor and stator are very fine – sometimes only a few mm to ensure efficiency is maintained.

If the liquid is at a higher temperature than specified at enquiry stage, the stator can swell due to the temperature reducing the gap between rotor and stator leading to abrasive wear of working parts. In extreme temperature fluctuations, this internal design may not be appropriate. Stators can swell between 20°C and 54°C.

Metal Rotors are often undersized to account for temperature fluctuations and can swell above certain temperatures which is why it is important to communicate all possible fluid temperatures at application stage.

One check to perform is that the temperature of the fluid at intervals during the day, matches that for which the pump was designed for. Also check the consumed amps, and whether pieces of rubber are found in the pumped fluid.

2. Chemical Attack

Pumping liquids which are not compatible with the fluid being pumped can lead to chemical attack. In some processes this can happen inadvertently, such as in waste fluid handling where stators can come into contact with a fluid it was not originally designed for such as oil, other chemicals or solid particles.

This can cause rotors to corrode, or stator geometry to be affected – the stator grooves to be elongated no longer forming the opposing shape of the rotor.

Should the pump stator swell, this can cause it to contact the rotor, shortening its life through wear, dry running as it swells and fluid can no longer lubricate it and cause other O rings to swell, meaning the pump begins to leak or other parts to corrode and disintegrate causing the unit to fail.

One check to make is to disconnect the pump from the pipework to establish if the stator has swelled and is protruding from the end of the pump, conversely, it is also possible for it shrink.

Further investigations can be made by dismantling the pump, checking the stator and rotor for signs of chemical attack such as exposed metal under the chrome plating applied to steel or cast-iron rotors, with the coating appearing pitted or with holes. Cracks can appear in stators exposed to incompatible chemicals.

3. Suction Head

If the suction head is too high in an application, it is possible for the pump to cavitate due to lack of suction pressure.

A symptom of this will be reduced flow, vibration, popping sounds and small holes in the stator causing it to appear pitted.

4. Dry Running

When a pump operates without fluid it is called dry running. In a progressing cavity pump this causes the stator to rub against the rotor without lubrication causing the high levels of friction to burn against the rotor.

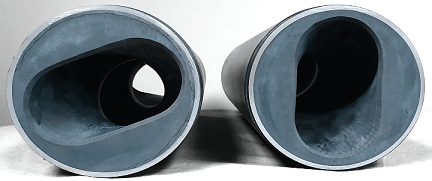

A symptom of this happening is when the unit is dismantled, the rotor will have rubber bonded to the rotor. The stator could also have gouges, an orange peel appearance, blisters and with the geometry torn and deep abrasion. They can also become soft, and sticky, with a tell-tale scent of burning.

It is possible for pieces of rubber to appear in the final pumped product. If the pump frequently trips the breaker fuse, this could be a reason why.

Setting up a control panel to detect high amp consumption, or a temperature probe fitted into a drilled stator will indicate when the pump is operated without fluid and stop it prior to damage occurring ensuring stator protection.

5. Abrasive Fluids

When a fluid is highly abrasive and pump speed is too high, it can lead to scoring, chunks of the stator to be removed, and pump performance to be reduced due to lack of efficiency. If pump performance has reduced this could be a symptom, as well as pieces of rubber in the pumped fluid.

6. Excess Pressure on Outlet

Excess pressure on the outlet can cause the pump stator to fail prematurely, due to it working at the limits of its design. Progressing Cavity pumps are typically built to withstand 24 bar pressure or 48 bar.

If the duty point is closer to the max pressure for extended periods of time, it is better to opt for a larger pump which can accommodate the large pressures with larger safety margin.

7. Delamination

Delamination occurs when the elastomer molecules do not form strong enough cross-sectional bonds, resulting in a layer like structure creating weak areas.

During operation the stator can then begin to break up, leading to loss of performance such as reduced flow and pressure, heavy vibration, and rubber pieces to be present in the final pumped product.

That covers the common 7 causes of stator failure. If you are experiencing frequent issues with your pump stator and are unsure of the cause or how to resolve, speak to North Ridge Pumps to see if they can help.